Lessons I Learned From Tips About How To Check A Cylinder Head

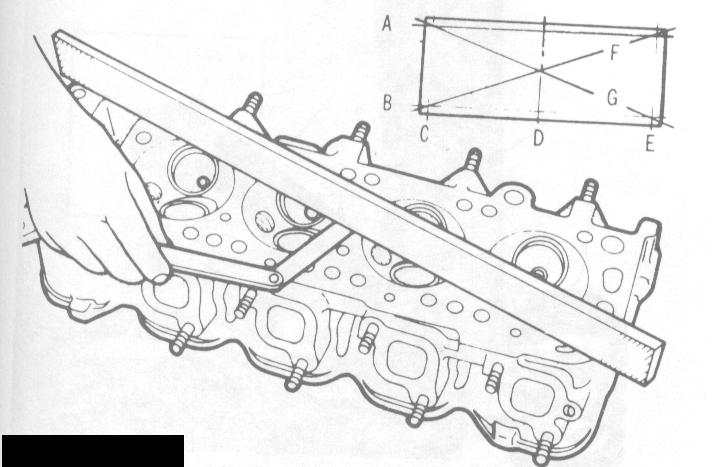

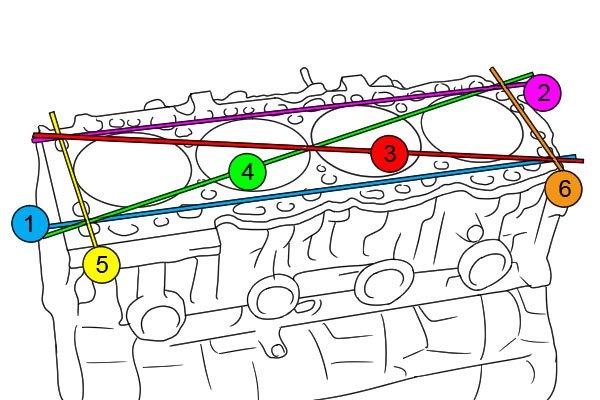

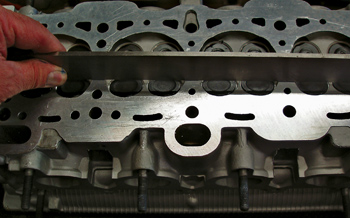

Place a straightedge on the cylinder head diagonally from corner to corner.

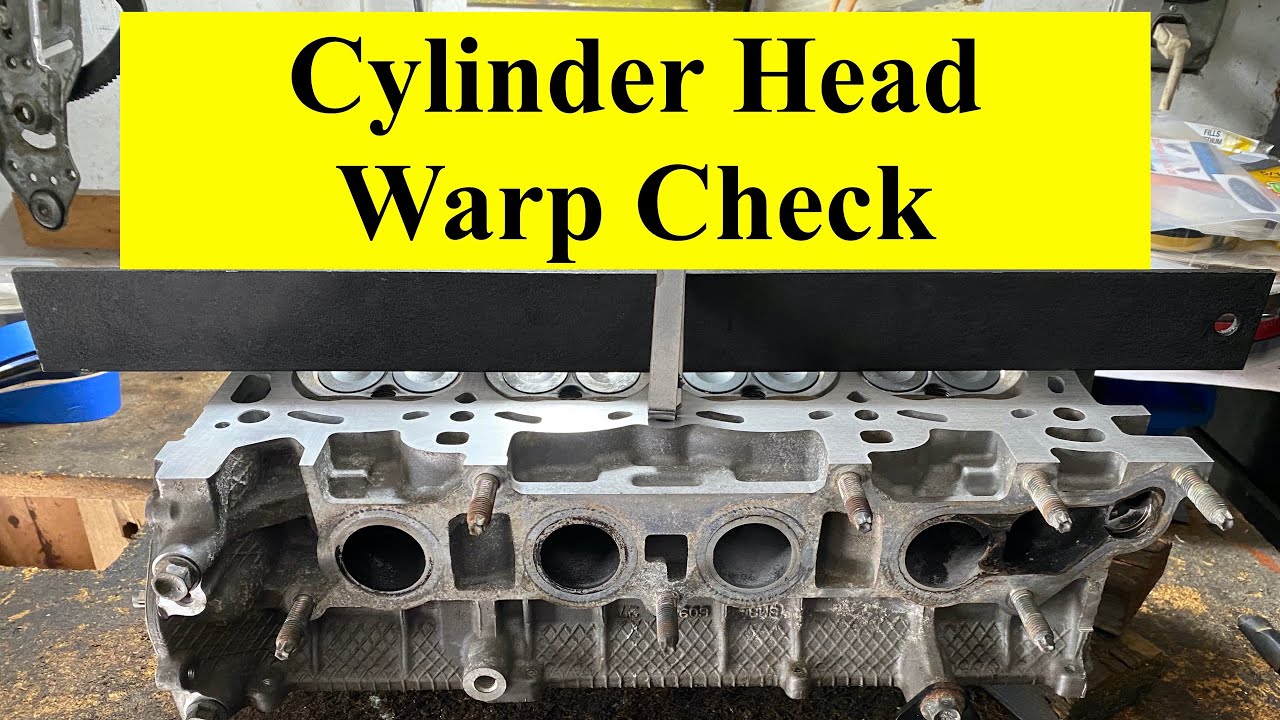

How to check a cylinder head. Cylinder head inspection methods flatness cylinder head inspection. This is a simple way to detect a warped cylinder head. He also shows how to use a profilometer to measure.

If you have a cracked head, you can expect oil to leak out of it. If the malfunction is large enough, there will be warning lights illuminating on your dashboard. Maintain and check your drive belt.

Flatness can be checked by placing a straight edge on the face of the cylinder head or block, and then using a feeler gauge to check any gaps between the straight edge and head or block. Dream big, be fearless, take risk, challenge everything and put jesus christ at the center of it. It also does not require rare.

First of all, the head being tested needs to be completely clean. As an owner of an older vehicle or boat, you may be running into problems. Set your feeler gauge at.003 inch, and place the gauge between the straightedge and the cylinder.

Using a feeler gauge, john checks across and diagonally in a variety of spots on the cylinder head to check for flatness. Checking cylinder head surface finish & flatness. This is how i check cylinder heads for cracks/leaks at home.

To use the straight edge, place it on the face of the cylinder head or block, then use a feeler gauge to check any gaps between the straight edge and the surface. Symptoms of a cracked cylinder head. Before we go to the other techniques let us first discuss two of the simplest.